|

Papermaking is an involved multi-step process that can easily be simplified and adapted to a garage, kitchen, bathroom or outdoors. Pictured here are the basic elements of papermaking; pulp, vat, mould and deckle. |

|

Plant fiber is gathered and weighed to calculate the correct cooking solution. Common plant fibers used at the Green Door Studio are cotton, linen, hemp, kanaf, kozo, gampi and flax. Pictured here weighing cotton rag. |

|

Plant fiber is cut into small pieces and can be stored until ready to cook. |

|

Fiber is cooked in a caustic solution, using lye or soda ash. As shown here cooking is always done outdoors. |

|

The fiber is then rinsed and either beat by hand or by using a hollander beater. Pictured is Drew Cameron loading cotton rag into the hollander (1.5lb 1935 Valley) beater. |

|

The beating process separates the fibers from one another forming a slurry of pulp to the consistency of oatmeal. |

|

The slurry can be used immediately or it can be balled up and refrigerated for future use. Pictured here are different colors of cotton rag slurry that have been beaten. |

|

After the fiber has been beaten, the slurry is poured into a vat and diluted with water. By passing a mould and deckle through the diluted slurry, thin and uniform pulp sheets are formed. |

|

The thin sheets are then gently pressed and passed onto a synthetic felt (pellon). This action is called couching, pronounced 'cooching' (from the French couche - 'to layer'). This process is repeated, making a stack of sheets, creating the pellon. |

|

The water is removed by pressing the pellon, using a hydraulic press. |

|

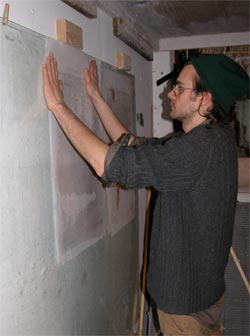

After pressing, the sheets are dried. At the Green Door this is either done by posting the sheets on glass or by hanging them in a loft dryer. Pictured here, sheets are being loaded onto a loft dryer. The unit is lowered for loading and then raised to the ceiling for drying using a pulley system. |

|

Sheets also can be posted on glass to dry. One side of the dried paper will have a sheen as a result of drying against the glass. |

|

After the sheets dry they are separated from the pellon, stacked and placed in a book press until they are used. |

|

Paper is commonly used for printing and bound into books using western and eastern bindings. Here an edition of 'perfect bound' sketch books await trimming in the guillotine cutter. |

|

The 23 inch Oswego guillotine paper cutter is a massive hand operated machine. It is used to remove the deckle edges from paper after binding. |

|